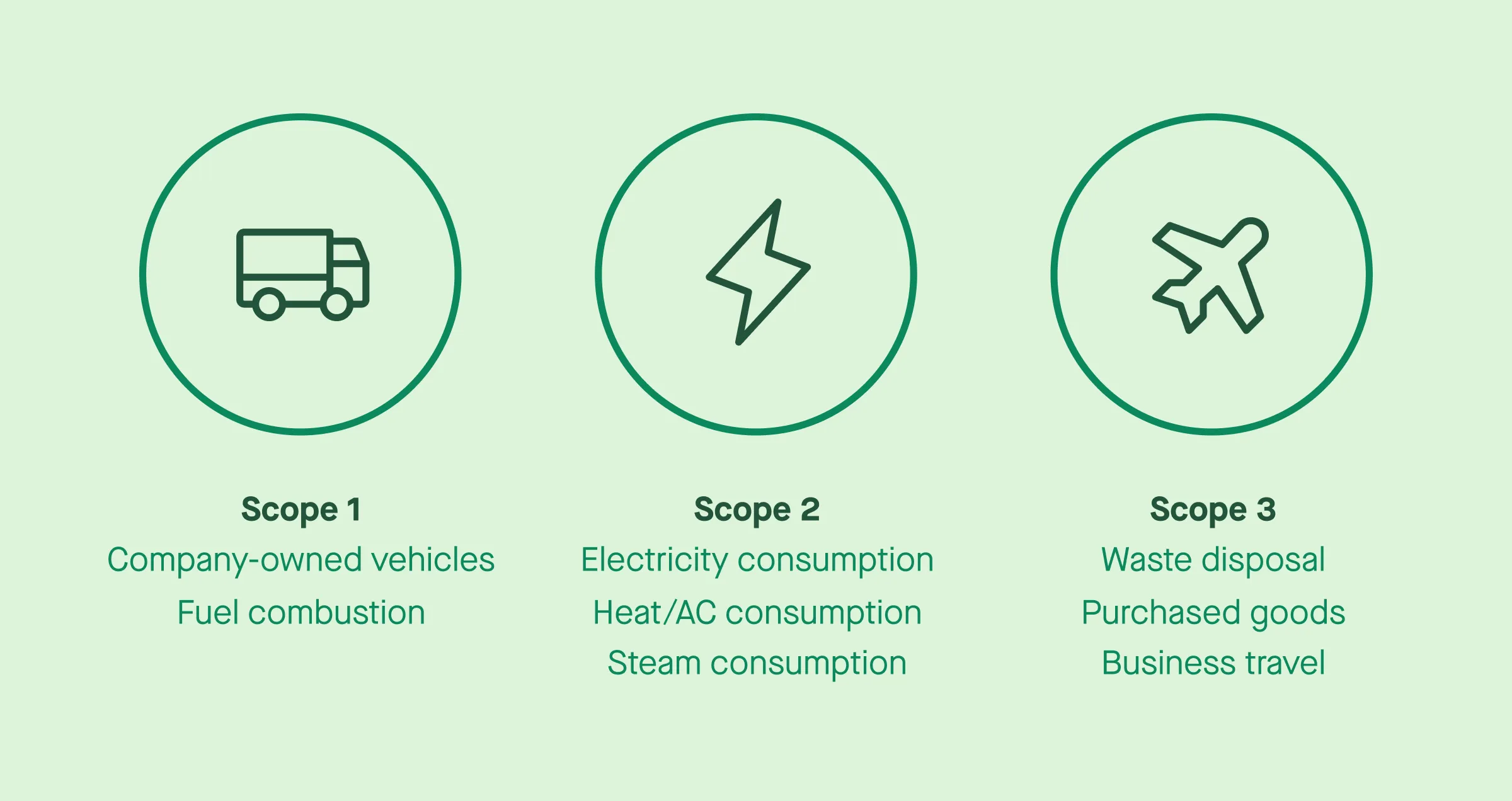

As the world moves closer to global climate targets, businesses are increasingly focused on understanding and reducing their environmental impact. For many organizations, Scope 3 emissions, which encompass all indirect emissions from a company’s value chain, represent the largest part of their carbon footprint. Unlike Scope 1 (direct) and Scope 2 (indirect energy) emissions, Scope 3 includes emissions from activities that occur outside of a company’s direct control but are integral to the production of the final product. These include emissions from suppliers, transportation, and even the downstream use and disposal of products.

What are Scope 3 emissions?

Scope 3 emissions, also known as value chain emissions, refer to the indirect greenhouse gas (GHG) emissions that occur throughout an organization’s value chain, both upstream and downstream of its operations. These emissions are not directly controlled by the organization but are a result of its activities, such as the production and transportation of goods, the use of sold products, and the end-of-life treatment of products. The Greenhouse Gas Protocol categorizes GHG emissions into three scopes: Scope 1 (direct emissions), Scope 2 (indirect emissions from energy consumption), and Scope 3 (indirect emissions from the value chain). Understanding and managing Scope 3 emissions is crucial for organizations to reduce their overall carbon footprint and mitigate climate change.

Why measuring Scope 3 emissions matters

Reducing Scope 3 GHG emissions is crucial for organizations looking to fully decarbonize. The GHG protocol, which provides a comprehensive framework for measuring and managing greenhouse gas emissions by categorizing them into three scopes, highlights the importance of tracking and addressing these emissions. For financial organizations, in particular, regulatory pressures and investor expectations around sustainability are growing, making the accurate measurement and reduction of Scope 3 emissions vital.

But why focus on supply chains specifically? According to the Carbon Disclosure Project (CDP), value chain emissions (including those from suppliers) are, on average, 11.4 times greater than the direct emissions from a company’s own operations. This makes reducing value chain emissions a high-priority task for businesses committed to sustainability. In this article, we’ll break down the concept of supplier tiers, explain how value chain emissions are measured, and explore how carbon accounting software can streamline the process.

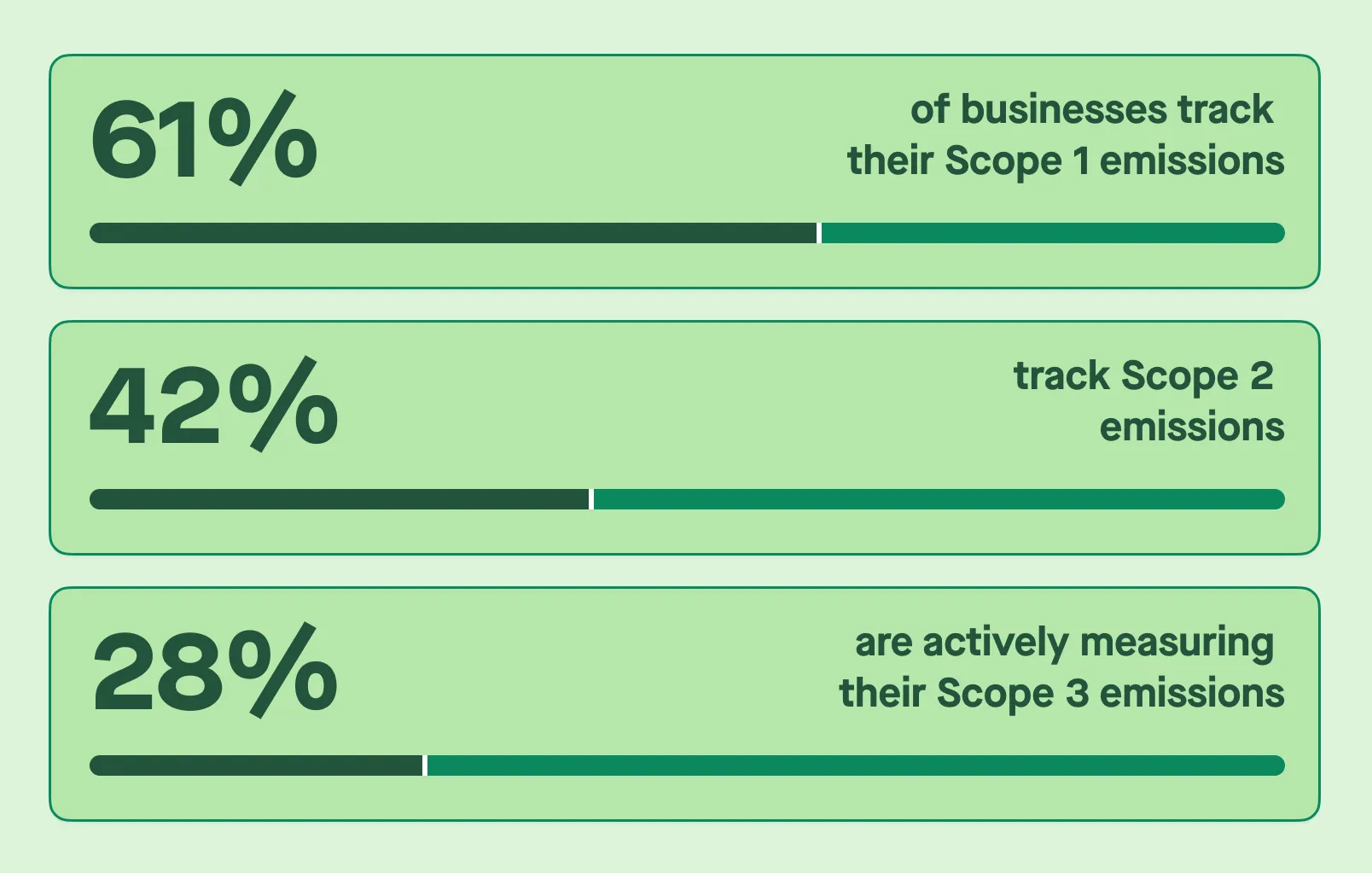

What the data reveals about Scope 3 measurement

Scope 3 emissions are the most challenging to measure, but also the most important. These emissions account for the majority of a company’s climate impact, particularly in industries that rely heavily on sourcing materials or have extensive supply chains. In sectors such as manufacturing, retail, and technology, Scope 3 emissions can account for more than 80% of a company’s total GHG emissions.

Effective supply chain management is crucial in navigating complex networks of suppliers, particularly in the context of supplier tiering. Understanding supplier relationships and mapping supply chains can enhance resilience, visibility, and ultimately contribute to a company’s success by addressing vulnerabilities and improving sustainability efforts.

Despite their significance, many businesses still struggle to measure and manage their Scope 3 emissions. In Sweep’s survey, Sustainability in Action: Harnessing the Power of Data to Unlock Sustainable Business Transformation, the data revealed that while 61% of businesses track their Scope 1 emissions and 42% track Scope 2 emissions, only 28% are actively measuring their Scope 3 emissions. The complexity of data collection from suppliers, compounded by the challenge of engaging third parties in the emissions reduction process, means that many businesses fall short in this critical area.

Yet, addressing Scope 3 emissions is not just about meeting regulatory requirements. It can lead to a range of business benefits, including:

Smarter procurement decisions

By knowing which suppliers are taking meaningful steps to reduce their emissions, companies can prioritize those partners in their procurement processes.

Cost reduction opportunities

Identifying carbon hotspots within the supply chain, including evaluating different supply tiers, can reveal areas where energy efficiency improvements can be made, leading to cost savings.

Improved stakeholder relationships

Demonstrating leadership in sustainability through transparent supply chain practices can enhance a company’s reputation among investors, clients, and regulators.

The importance of measuring and reducing Scope 3 emissions becomes even more apparent when we look at the global effort to mitigate climate change. With up to 60% of the world’s global emissions coming from supply chains, companies that take steps to reduce their value chain emissions play a vital role in global decarbonization efforts.

Understanding supplier tiers

When businesses begin the process of measuring their supply chain emissions, they encounter the concept of supplier tiering. This classification system organizes suppliers into different tiers based on their proximity to the final product and their importance to the business. Understanding these tiers is crucial for accurately mapping out emissions across the supply chain.

- Tier 1 suppliers: These are the direct suppliers that provide goods or services to your company. They typically have a close working relationship with your business and are the easiest suppliers to engage with when it comes to data collection on emissions.

- Tier 2 suppliers: Tier 2 suppliers provide goods or services to your Tier 1 suppliers. They are one step removed from your direct operations, which makes engagement and data collection more difficult, but still essential for understanding the broader climate impact of your supply chain.

- Tier 3 suppliers: These suppliers provide goods or services to Tier 2 suppliers and are often the furthest removed from your company. While they may seem peripheral, Tier 3 suppliers often have a significant role in sourcing raw materials and are an important part of understanding and reducing downstream emissions.

By focusing on all supplier tiers, businesses can gain a more complete picture of their GHG emissions and work to reduce emissions at every stage of the value chain.

Why visibility into your supply chain matters

Gaining supply chain visibility into the climate impacts of your supply chain is the first step toward effective carbon management. Categorizing suppliers based on their distance from the final product and their importance enhances understanding and decision-making. Without a clear understanding of where emissions are coming from, it’s impossible to know where to focus reduction efforts. For example, a company might reduce its operational emissions, but if it relies on a Tier 3 supplier that uses energy-intensive manufacturing processes, the overall GHG emissions from the production of the final product may still be high.

Effective carbon footprinting requires visibility not only into Tier 1 suppliers but also into Tier 2 and Tier 3 suppliers. Having this level of detail allows businesses to:

- Identify carbon hotspots: Knowing which suppliers are responsible for the highest emissions enables businesses to prioritize those areas for reduction.

- Engage suppliers: Once a company knows where its emissions are coming from, it can work with suppliers to implement more sustainable practices and reduce emissions across the supply chain.

- Drive collaboration: Encouraging suppliers to be more transparent about their carbon footprint and to adopt greener practices can foster a collaborative effort toward decarbonization, benefiting all parties in the value chain.

As regulatory requirements evolve, businesses that have a strong understanding of their Scope 3 emissions will be better positioned to meet compliance standards and demonstrate their commitment to sustainability.

Streamlining carbon accounting with effective software

Given the complexity of measuring and managing Scope 3 emissions across multiple supplier tiers, businesses need sophisticated tools to streamline the process. Carbon accounting software plays a key role in helping organizations track and reduce emissions efficiently.

Manual data collection from dozens—or even hundreds—of suppliers can be time-consuming and prone to error. With the help of software solutions, companies can automate much of the data collection process, ensuring that they receive accurate and timely information from their suppliers. This not only reduces the administrative burden on the procurement and sustainability teams but also improves the quality of the data being collected.

Effective carbon accounting software, such as Sweep’s platform, allows businesses to:

Centralize data collection:

A comprehensive platform consolidates emissions data from suppliers at all tiers, providing a complete view of the company’s value chain emissions.

Automate reporting:

Automated tools ensure that emissions data is regularly updated and compliant with reporting standards, such as those set by the GHG protocol.

Provide actionable insights:

By analyzing emissions data, software can highlight areas where businesses can make the most impact, whether that’s switching to more sustainable suppliers or encouraging existing suppliers to adopt greener practices.

One of the key benefits of using carbon accounting software is the ability to track downstream emissions, which are often the hardest to measure. By gaining visibility into the emissions associated with the use and disposal of the end product, companies can further refine their decarbonization strategies.

Moving forward: How to act on your supply chain emissions

To successfully reduce GHG emissions across your supply chain, there are several key steps that businesses can take:

- Engage your suppliers: Start by focusing on your Tier 1 suppliers, where you have the strongest relationships. From there, work your way through the tiers, encouraging transparency and collaboration at every level.

- Set joint sustainability goals: Partner with your suppliers to set shared climate targets and ensure that you’re all working toward the same goal of reducing emissions.

- Leverage technology: Use carbon accounting software to streamline data collection and reporting, and to gain insights into the most effective ways to reduce emissions across your supply chain.

- Measure and track progress: Regularly monitor the emissions from your suppliers and evaluate your progress toward your decarbonization goals. Make adjustments as needed to ensure that you stay on track.

Collaborating for collective action

Reducing Scope 3 GHG emissions is essential for companies committed to making a meaningful impact on climate change. While the task of measuring and reducing supply chain emissions can seem daunting, it is achievable with the right tools and a clear strategy.

By gaining visibility into their supply chains, engaging suppliers at all levels, and using effective carbon accounting software, businesses can reduce emissions across their value chain, improve regulatory resilience, and enhance their reputation in the market. Most importantly, they will contribute to the global effort to combat climate change, one supply chain at a time.