Three ingredients for an effective calculation

There are three key ingredients needed for a robust calculation of your supply chain emissions:

- The right measurement method for your baseline

- A clear map of all your supply chain contributors

- Tools to collect accurate data from the most important suppliers

Let’s go through each of these in more detail.

1. Select the right method based on your data

The best method for establishing a baseline measurement for your supply chain emissions depends mostly on the supply chain data at your disposal and the resources available for tracking and measuring emissions. Below, we give you an overview of the four key ways to calculate the carbon footprint of your supply chain. Sweep helps you to select the right method based on your data maturity.

Four methods of measurements

Industry averages – These are sectoral emissions factors, or averages of the emission data submitted by organizations operating in a given sector. They can be used as a starting point for carbon footprint calculations in the absence of more accurate data.

Spend-based – This is based around the cost of purchased goods or services. The value is multiplied by a given emission factor to calculate an estimate of your total emissions. Spend-based emission factors are derived from an industry average of emission levels usually at a national level. This means they aren’t super accurate. On the plus side, spend-based methodology is relatively simple to implement and can provide a useful approximation of your company’s indirect emissions.

Supplier-based – As this is primary data, it is the most accurate form of Scope 3 accounting. It involves tracking the emissions from individual suppliers, and then using that data to calculate the emissions associated with your company’s purchased goods and services.

Hybrid – The hybrid method uses a mix of the above methodologies. It usually presents a fairly accurate picture of your total emissions, but it can be complex and resource-intensive to implement.

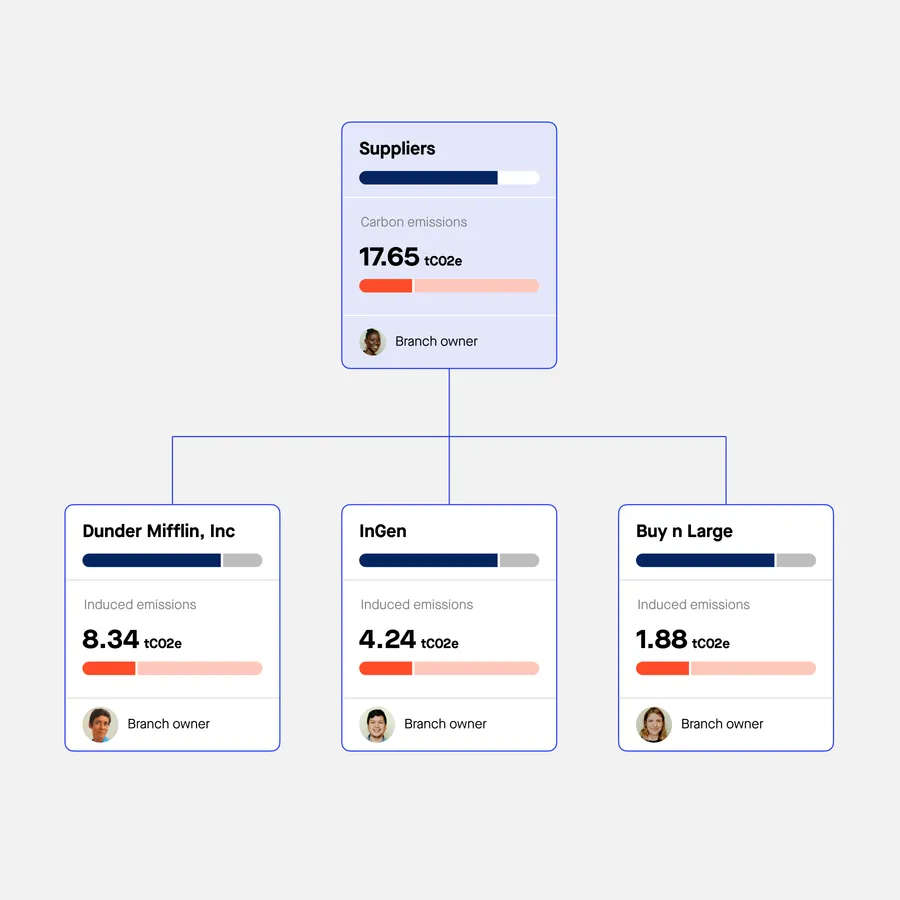

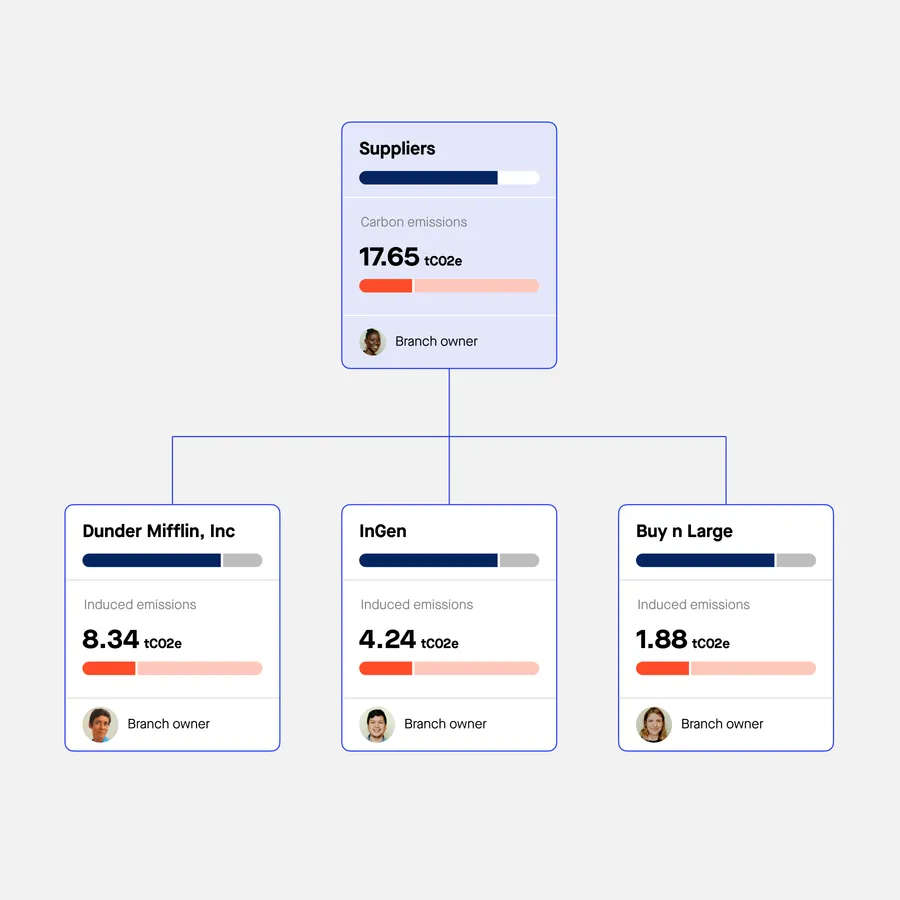

2. Map your supply chain contributors

Mapping your supply chain contributors is crucial as it gives you a clear picture of the activities, processes, and systems involved in the entire chain. It also helps you identify your top emitters.

With a clear map (which we refer to as a ‘Tree’ in Sweep) you’ll be able to visualize exactly what data you’ll need and from whom. You can also use this to conduct a baseline measurement of your emissions using the data that you have at your disposal.

“We need to demystify the challenges of supply chain emissions. It starts with empowering teams and supplier educational resources and user-friendly tools like Sweep. When I started digging into QIMA’s carbon footprint, Sweep’s Tree was incredibly helpful to understand, structure, and get a full overview of our global emissions. That’s a key step to identifying missing data and our main emission sources, and taking action from there.” Anouschka Jansen, Director Sustainability Solutions at Qima.

3. Collect more accurate data and set targets

Focus on the strategic suppliers using the Pareto principle of 80-20: 20% of your suppliers are likely responsible for 80% of your carbon footprint.

Focus on these suppliers first, and get them on board by making more exact data collection as simple as you can. Provide your procurement and sustainability teams tools to automate data collection for purchased goods and services. Empower them to send surveys to suppliers to collect missing data.

Since using Sweep, they’ve obtained a dynamic and granular view of their carbon footprint and reduction efforts across their entire company and value chain. Read about their climate journey.

The Sweep methodology

If you don’t have exact supplier-based data at your disposal, don’t worry. You can still obtain a baseline measurement for your supply chain emissions. Our platform is specifically designed to suit companies with varying levels of data maturity.

We can help you:

- Model your supply chain using benchmark data and identify your emission hotspots. We use industry averages and spend-based data as a starting point.

- Send each supplier a straightforward climate survey. This is the first step to embarking on their own climate journey and tracking the impact of their actions. Note that you can adapt our climate surveys to make them suited to your needs.

Remember: climate action is not a straight line

It’s tempting to think that taking climate action is a four step, linear process: measure, set targets, reduce, communicate… Although – for the sake of clarity – this guide addresses each of these elements, the reality is somewhat different. In fact, a climate action pathway is best seen as of activity, moving ever outwards.

Your company can begin measuring its carbon footprint using benchmark data. Use this to set targets and engage in reduction activities across your supply chain. But once you start reducing your emissions, you need to reach a deeper level of accuracy with your carbon measurement. Here, getting data directly from your suppliers is crucial.

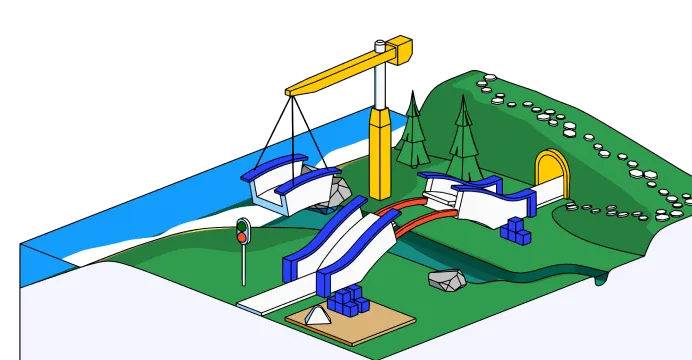

The below diagram shows how your climate action should evolve and grow – from a straightforward baseline measurement, to a comprehensive reduction strategy involving your entire value chain.

Once you’ve measured your emissions, the next step is understanding how to communicate them to your internal and external stakeholders in an understandable way. Below are two commonly used approaches.

This is based around the cost of purchased goods or services. The value is multiplied by a given emission factor to calculate an estimate of your total emissions. Spend-based emission factors are derived from an industry average of emission levels usually at a national level. This means they aren’t super accurate. On the plus side, spend-based methodology is relatively simple to implement and can provide a useful approximation of your company’s indirect emissions.

Measuring a product’s carbon footprint is valuable for procurement because it gives you an at-a-glance overview of the environmental impact of the products that your company is purchasing and using. This information can be used to make informed purchasing decisions and can help reduce your overall emissions – while identifying potential cost savings.

With Sweep, you can define your product system boundaries i.e. all the activities, processes, and suppliers involved in producing and delivering your products to the end user. You can then efficiently collect climate data from your entire value chain.

You’ll obtain a robust estimate of the carbon footprint for that particular product – giving you greater purchasing power.

_Iw12l.webp)